Did you know that approximately one million plastic bottles are purchased in the world every minute? The figure, based on a study carried out by Euromonitor in 2017, demonstrates the extent to which this product is present in daily life and that the need to give this waste an appropriate destination is urgent. PET (polyethylene terephthalate) bottles are used to package water and soft drinks and this material can be recycled several times. Taking that into account, a group of students discovered how to transform the containers into a device that helps patients with health problems linked to trauma, central-level diseases, such as cerebrovascular accident (CVA), motor deficiencies at the level of the hand, fingers, and others.

The innovation was a finalist in the 10th edition of Solve for Tomorrow Peru, in 2023. Called “SIFT – Health, Innovation, Splint and Technology”, the project was developed by students from the School Mayor Secundario Presidente del Perú (COAR Lima). They are boarding school students, between 16 and 17 years old and in the fourth year of secondary education, that is, the second to last year of compulsory schooling. “They are students with little availability of time, and they also did the project outside of academic hours. Therefore, we sought to form the team with students willing to make this extra effort,” reports the mediator teacher, Erik Vidal.

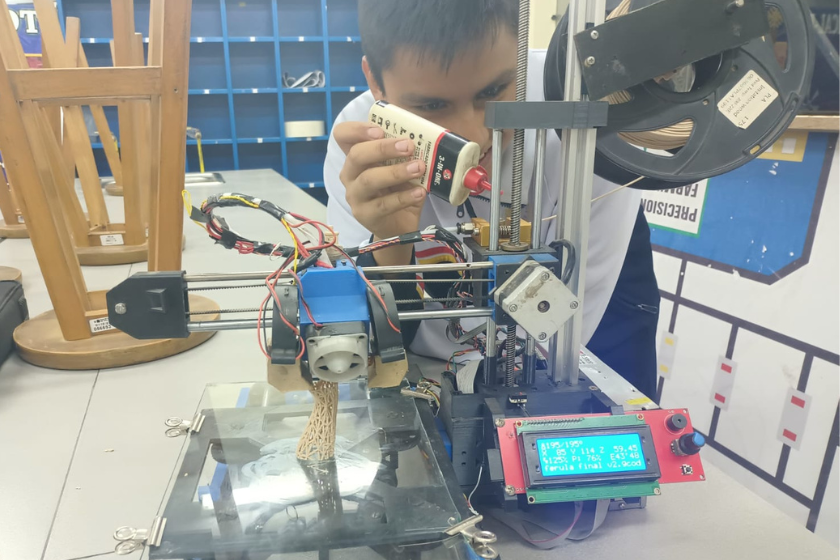

The creation uses a 3D printing machine to make splints with resin made from recycled material, which were donated to patients at a local hospital complex. The splint is a device that is applied for physiotherapy and fracture treatment or medical rehabilitation. It is a device that immobilizes the hand, relieves muscle pain and prevents contractures.

The project began before Solve for Tomorrow, from the subject “Technology for Entrepreneurship”, where it is taught the methodology of finding a real problem based on inquiry, doing research and looking for possible solutions. But the idea extrapolated the limits of the class.

Promotion of the economy and sustainability

The first idea was to create a machine to use PET bottles for recycling. “It was created here at school, with the students, a machine that transforms PET bottles into filament for the 3D printer. That’s where it all begins,” he explains. They thought that the creation could be like a business because the cost reduces, since the filament generally comes from China.

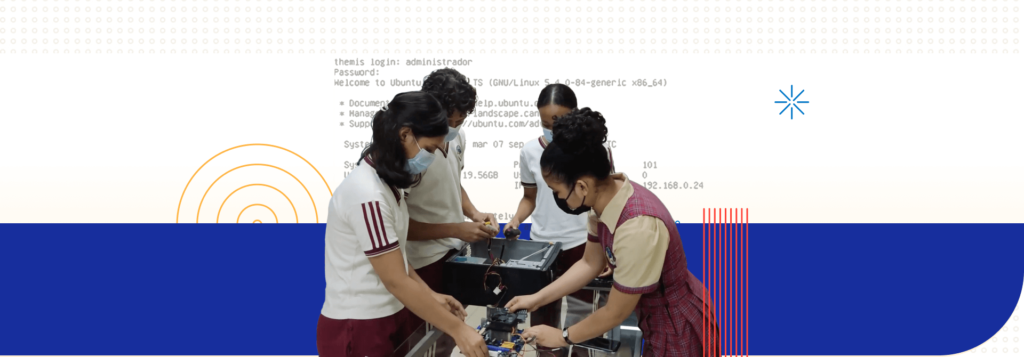

By putting their hands to work, they learned to perfect the process, which basically consists of heating the bottle, then cutting it and pulling it, forming a thread that will be the input used to manufacture the splints. Now that they had the basic material, how to do the production? The school didn’t have a 3D printer, so they used the one a student had at home.

When this stage was ready, a new challenge arose: what to do with the filaments. They looked for problems that could be solved with the plastic thread. The teacher knew the director of a hospital and they had the opportunity to visit him and see that there were many cases with carpal tunnel problems. They connected the dots: they had a more sustainable material and the hospital had a constant need of splints. Why not make them with PET bottle filaments?

“At the hospital they thought they were finishing their university degree in medicine and were surprised when they discovered that they were college students. The experience was beautiful,” says the proud teacher. The issue was completely new to the team, but they delved deeper into the topic. “In addition, there was another challenge: how do we standardize the splints, if people’s hands are not the same?” says the educator.

The experience was a lesson in how to behave professionally, being responsible and assuming mistakes, as well as making the necessary corrections. That is, knowing that this is part of the creative process.

With the lessons learned, the students improved the design and, when the prototype worked in the new version, the students were very happy with the result and said that the experience had renewed their hope that technology can be useful for society. “Patients would be delighted to see young people taking an interest in a problem they live with, because getting the splint is one more step in their healing process,” adds the teacher.

For 3D design, they used the free professional software, Blender. “Some of the team were empowered by making contacts at universities to have quick courses on the subject and then they themselves began to explore the tool,” adds Vidal.

From school project to a Technology Center

The school prepares young people to study in other countries and some of the team have already been accepted for the exchange, while others are preparing for it. However, the teacher plans to continue with the project with students who have availability. The educator has negotiated with the hospital so that in 2025 they can implement the first Technology Center dedicated to rehabilitation in the institution. “We are looking for allies and we are going to implement the machine we have created, build and donate a 3D printer and train the technician designated by the hospital so that they can make the products themselves,” he says.

The objective is to reduce hospital costs and promote the technical capacity of professionals. Additionally, some of the students began to study an alternative to filter to eliminate the impact of the gas produced when plastic is burned.

Changing the world from school

The educator highlights that this experience has changed the way students see their role in the world. “They now see that knowledge can be turned into a real solution and transform their realities. I have also learned a lot. I think we need agents of change. Programs like Solve for Tomorrow are very important to value young people’s initiatives,” he concludes.