The so-called “cooking gas” or LPG is very common for preparing food in Brazil. According to the National Union of Liquefied Petroleum Gas Distribution Companies (Sindigás), 91% of households in the country rely on these cylinders. However, the average price of 13 kg cylinders has grown by 44% in the last five years, from R$69 in January 2019 to R$100 in the same month in 2024 [approximately going from 12 to18 US dollars]. Upon seeing news about this increase, a student had the idea of creating a method to make the gas last longer.

The innovation was called “Fogão Híbrido (FH01)” (Hybrid Stove, in English) and was a finalist in Solve for Tomorrow Brazil, in 2022. The student joined two other classmates, all from the 2nd year of secondary school (penultimate year of compulsory schooling) at the Nossa Senhora de Nazaré State School. The goal was to help families to save money without resorting to unsafe and polluting alternatives, such as burning alcohol and firewood. This is because the price of gas weighs on the budgets of low-income people, who sometimes rely on government social assistance programs. On average, this aid amounts to R$ 686.10 per month [equivalent to approximately US$ 123] for each family.

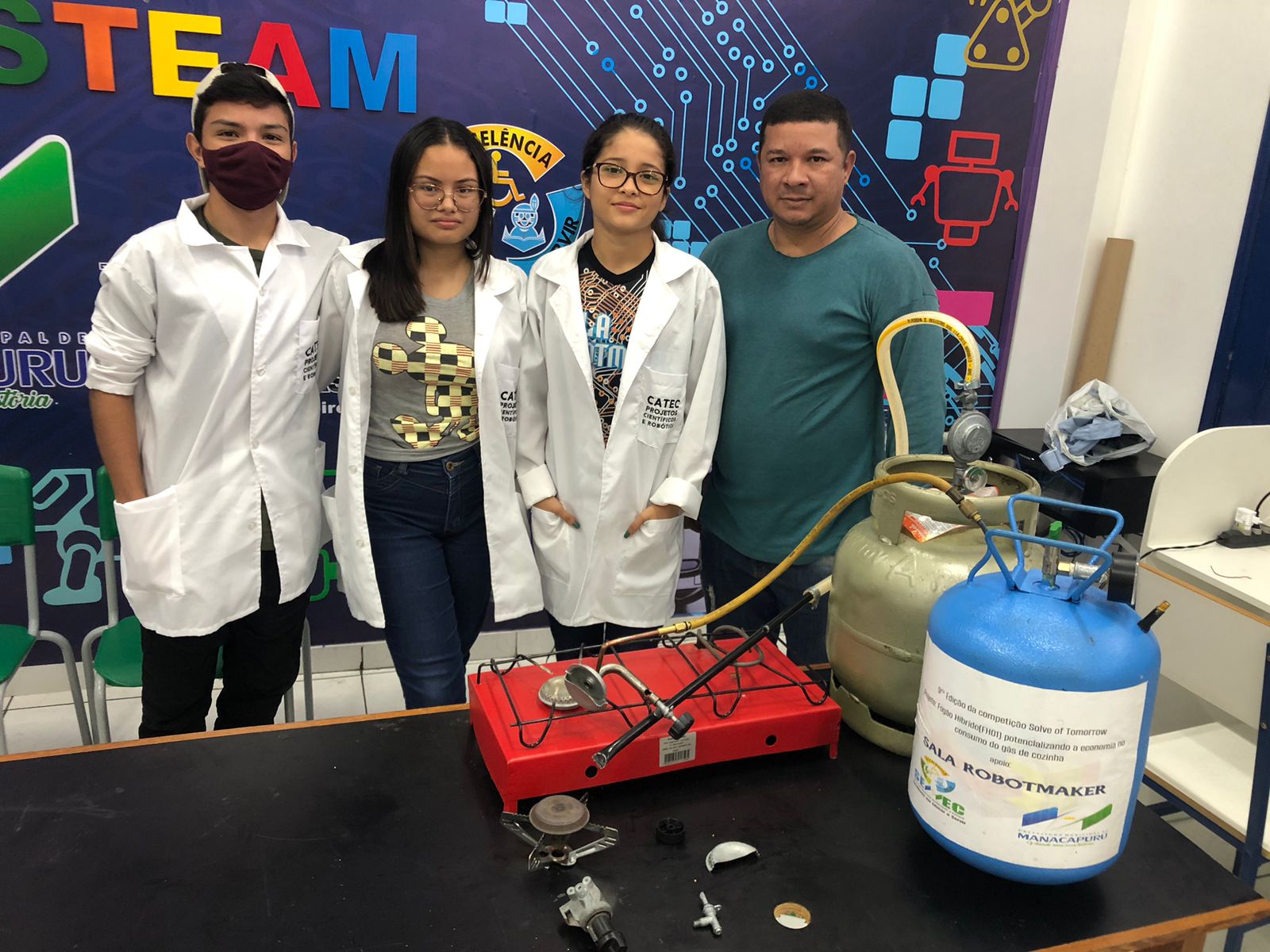

Robotics education is a highly encouraged topic in the state and municipal education systems of the city of Manacapuru, in the state of Amazonas, northern Brazil. As such, students are already used to developing projects and submitting them to various competitions and programs. When the “Fogão Híbrido (FH01)” team decided to sign up for Solve for Tomorrow, they sought out Galileu Pires, a Biology teacher who also has a degree in Mechanical Engineering and was the mediator of the project, together with Chemistry teacher Alessandro Couto.

The first step was to study fire using multidisciplinary approaches, which involved Physics, Chemistry, Engineering, Biology, and Social Sciences.

More than just a prototype, the students managed to create something of socio-environmental and economic value. The project was born from scratch; it is unprecedented. And with this, they also learned to believe in themselves. Their ability to create is the same as from students in the capital and anywhere in the world, all they need is the will, says the educator.

Experiments proved the results

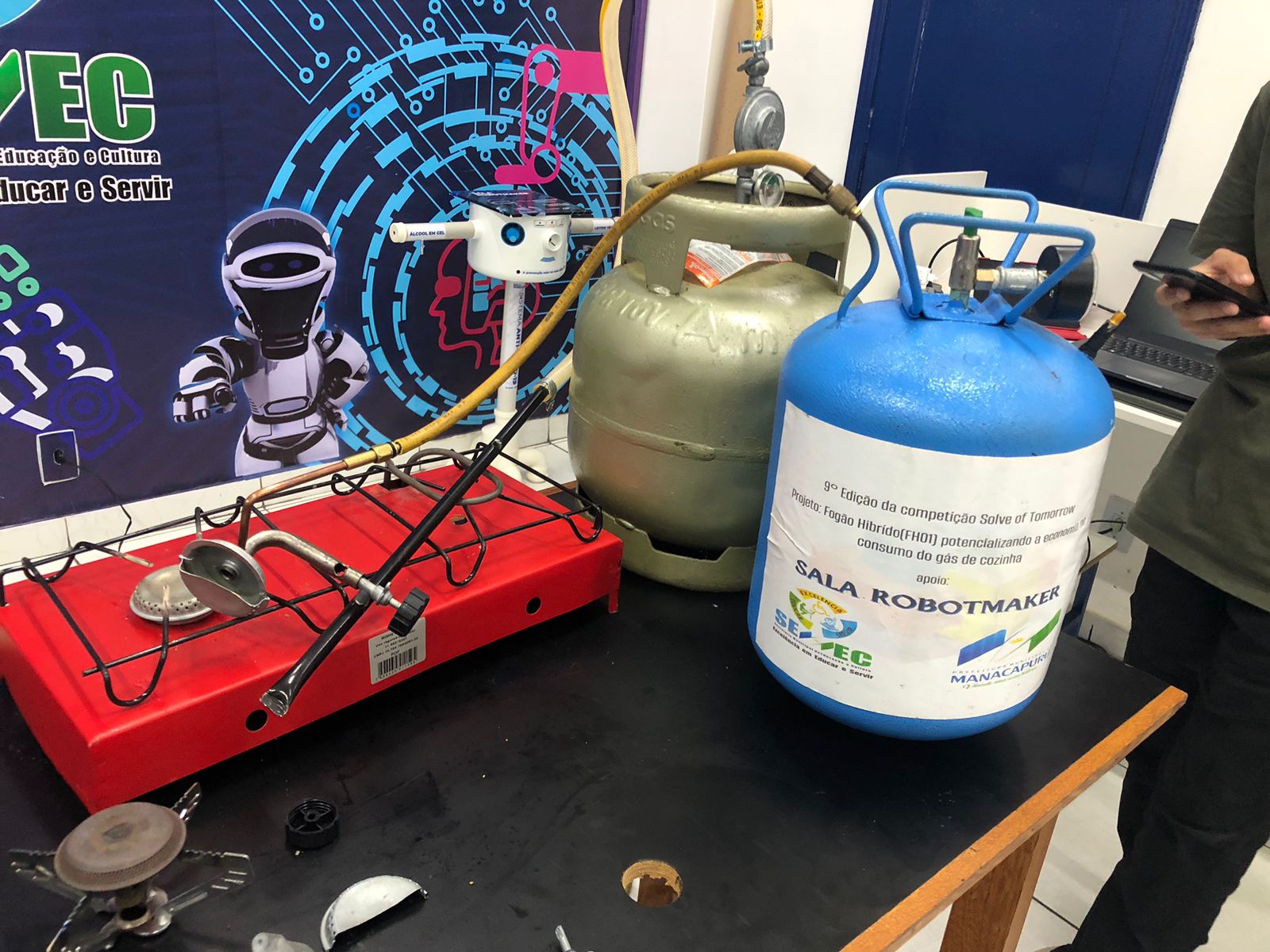

The students combined a common stove with an oxygen cylinder reused from an air conditioner, valves for safety and control over the release of gasses, a pressure gauge, an oxygen supply, and hoses. In the first test, the equipment that the students assembled worked very well.

On the largest burner of a conventional stove, the water took 10 minutes to reach 100°C, while on the smallest burner, it took 5 minutes. Another test was with frying nuggets, which also reduced the preparation time by 50%, with the lowest gas setting. “It was hopeful for us to see the possibility of a family buying a gas cylinder and doubling the time it could be used at home. No one would have imagined that a problem shown on television, in the news, would turn into a truly functional project”, recalls the teacher.

To be commercialized one day, the prototype will need to be built in an industrial process, with its materials and an autonomous pump that constantly supplies oxygen. “We adapted an oxygen cylinder to our reality. So, whenever it ran out in the middle of the experiment, the students had to go to a gas station to refill it using tire inflating machines. This is an improvement that can be left for the industrial stage,” says the mediator.

To achieve better results, the team added a preheating system around the burner to the prototype. With it, an electrical resistance heats the air in the room before the gas flame starts to burn. This increases efficiency and contributes to saving LPG.

Tests prioritize safety

Galileu Pires says that safety was a priority when building the prototype. The teacher contacted partners from the City Hall and the school management who helped to acquire materials produced following Brazilian technical standards. In addition, to avoid accidents, the experiments were carried out on Saturdays, with a minimum number of people in the room. The Fire Department was also notified to provide support.

“The support from the City Hall was very important for us to buy the materials. We wrote the purchase request letter, and they quickly set a date to deliver the funds and provided a vehicle with a driver to take us to Manaus, buy the materials, and bring them to school,” says teacher Galileu Pires.

The school encourages STEM approach

Since 2019, the school has encouraged project-based learning, because of the teacher’s participation in other editions of Solve for Tomorrow. In 2019, he even mediated one of the winning projects of the Popular Jury. According to Pires, the change came when the school allowed students free access to the Science lab. “I think that if students don’t try it, they will never know the pleasure of working with research. The school had a lab, but not all teachers had experience using it as a pedagogical practice with students. At first, it was difficult, I had to defend the idea of opening the intact lab and letting students use it even if the materials broke in the process. I started to pass on the knowledge I had, and the lab stopped being a decoration in school”, he says. With the culture of learning by doing, students and teachers started to test theoretical knowledge together and develop more scientific solutions to everyday problems.

Today, the young people involved in the project have already entered college and are doing internships with teacher Galileu Pires, encouraging other students to follow the path of science. “They are like monitors, supporting students so they can learn properly, guiding them with their logbooks, action plans, and field research. People already see in them the potential and self-confidence to work with science,” says the educator.

The mentoring offered within Solve for Tomorrow also helped develop new perspectives on research, according to Pires. “With the mentors, the students interact with highly educated people, with a different mindset, talking and sharing ideas. We are not the owners of the truth, what I can’t see, someone else can see and this adds to the project. The mentoring was very important for them, it helped a lot”, he highlights.